ASTRA - Applied Ventures

Applied Materials, a market leader in semiconductor capital equipment, struggles in automating in mass production, at their locations in Austin, Texas, Singapore, and Taiwan.

The rapid evolution of semiconductor technology, with components typically having a manufacturing lifecycle of around 3 years, creates challenges for manufacturers and OEMs.Advances driven by Moore’s Law, demand for performance in sectors like AI and IoT, and short lifecycle components lead to replacement faster than expected. This results in system redesigns, risks of counterfeit parts from grey markets, and inventory management issues, especially for industries with long product lifecycles.

The rapid evolution of semiconductor technology, with components typically having a manufacturing lifecycle of around 3 years, creates challenges for manufacturers and OEMs.Advances driven by Moore’s Law, demand for performance in sectors like AI and IoT, and short lifecycle components lead to replacement faster than expected. This results in system redesigns, risks of counterfeit parts from grey markets, and inventory management issues, especially for industries with long product lifecycles.

Frequent changes in product designs require production lines to be highly adaptable, capable of adjusting to varying environments, part sizes, and shapes. This dynamic setting makes traditional robotic solutions inadequate and manual labour expensive.

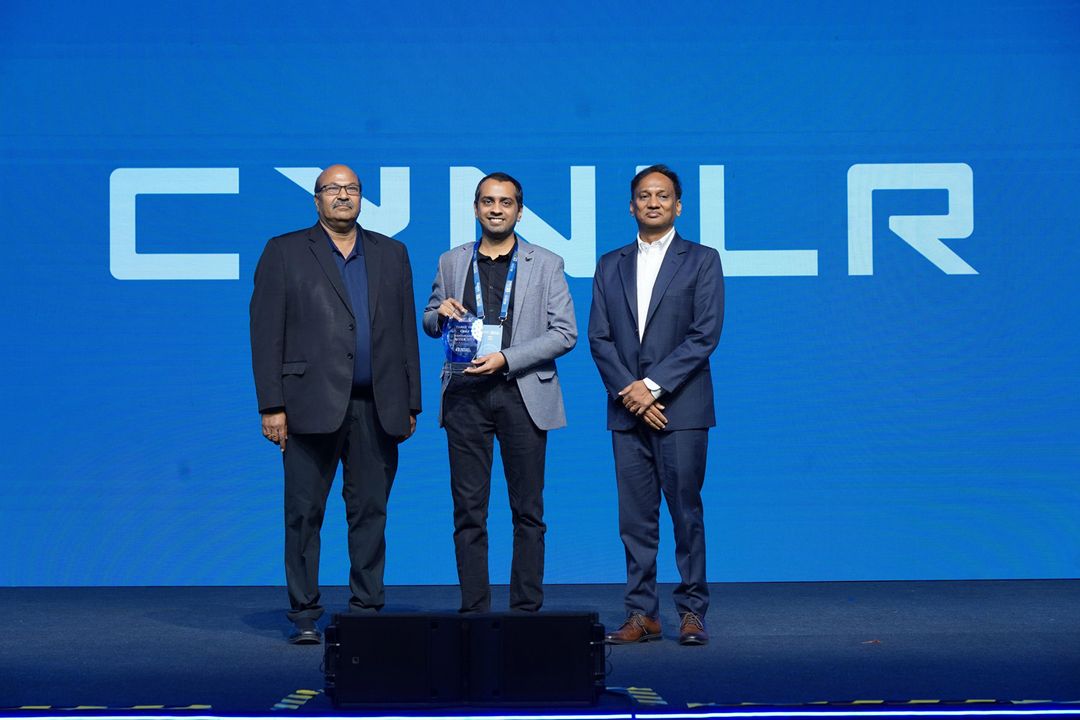

Applied Materials is keen on using CynLr's vision-guided general-purpose robots to automate their manufacturing and has selected CynLr as one of the startups in the fifth cohort of the ASTRA program, recognizing its potential to address key challenges in the deep-tech industry, including semiconductor technology, software, supply chain, and advanced manufacturing.